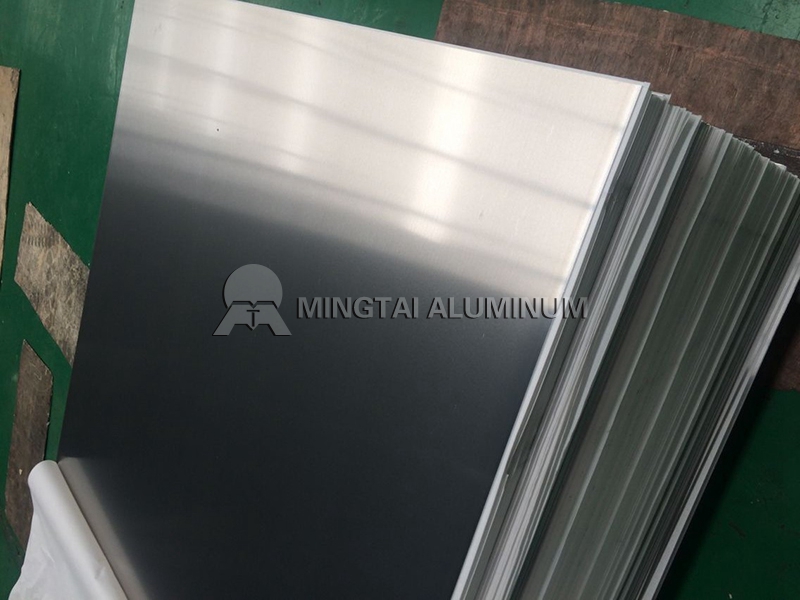

Introduction of 6063-T Aluminum Plate

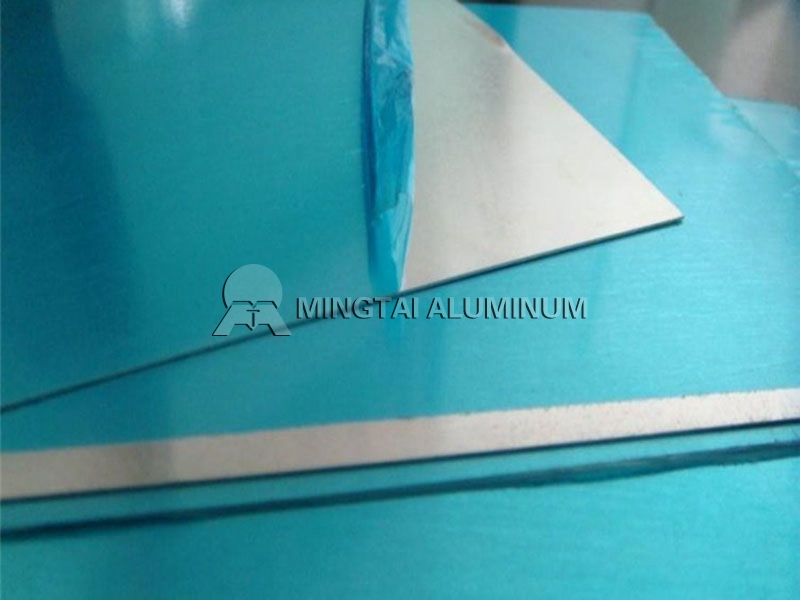

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

The T is one of the five main states of the aluminum plate. There are many T-state products of the 6-series aluminum plate The most commonly used is the 6063 aluminum plate. Today, Mingtai will introduce you to 6063-T aluminum plate.

Introduction of 6063-T Aluminum Plate

6063-T aluminum plate represents that the aluminum plate has been stabilized after heat treatment. According to different aging and processing techniques, the T state is subdivided into many subdivision states, which means that the aluminum plate has different properties. Here is a brief introduction to the T0-T10 status of 6063 aluminum plate.

Introduction of 6063-T0- T10 Aluminum Plate

T0 state, This is a state after solid solution heat treatment and natural aging and then cold working. It suitable for products that have been cold worked to increase strength.

T1 state: It is cooled by a high temperature molding process, and then naturally aged to a substantially stable state. Applicable to products that are cooled after the high temperature forming process and are not subjected to cold working (straightening and leveling, but without affecting the mechanical properties).

T2 state: cooled by a high temperature molding process, and naturally aged to a substantially stable state after cold working. It is suitable for products that are cooled by high temperature molding process, cold worked, or straightened and leveled to increase strength.

T3 state: cold working after solution heat treatment, and then natural aging to a substantially stable state, suitable for cold working or straightening after solution heat treatment. Leveling products to increase strength.

T4 state: natural aging to a substantially stable state after solution heat treatment. Applicable to products that are not subjected to cold working after solution heat treatment (straightening and leveling, but not affecting the limit of mechanical properties).

T5 state: It is cooled by a high temperature molding process and then subjected to artificial aging. It is suitable for products that are artificially aged after being cooled by a high-temperature molding process without cold working (straightening and leveling, but not affecting the limit of mechanical properties).

T6 state: a state of artificial aging after solution heat treatment. Applicable to products that are not subjected to cold working after solution heat treatment (straightening and leveling, but not affecting the limit of mechanical properties).

T7 state: similar to T6.

T8 state: After solution heat treatment, it is cold worked and then subjected to artificial aging. Suitable for products that have been cold worked, or straightened, leveled to increase strength.

T9 state: the state of artificial aging after solution heat treatment, and then cold working. Suitable for products that have been cold worked to increase strength.

T10 state: After being cooled by a high temperature molding process, it is subjected to cold working and then artificially aged. Suitable for products that have been cold worked, or straightened, leveled to increase strength.

What is Solution Heat Treatment?

The solution heat treatment refers to a process in which the alloy is heated to a high temperature single-phase region and maintained at a constant temperature, so that the process in which the intermediates are sufficiently dissolved in a solid solution and then rapidly cooled to obtain a saturated solid solution.

What is Natural Aging?

Natural aging refers to placing the workpiece under natural conditions such as outdoor, so that the internal stress of the workpiece is naturally released, and the residual stress is eliminated or reduced.

What is Artificial Aging?

Artificial aging refers to heating the workpiece to a certain temperature. After a long time of heat preservation (5-20 hours), it is cooled with the furnace or is cooled in the air. It saves time compared to natural aging, and the residual stress removal is more thorough, but the stress release is not complete compared to natural.