Die cast aluminum sheet surface treatment

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

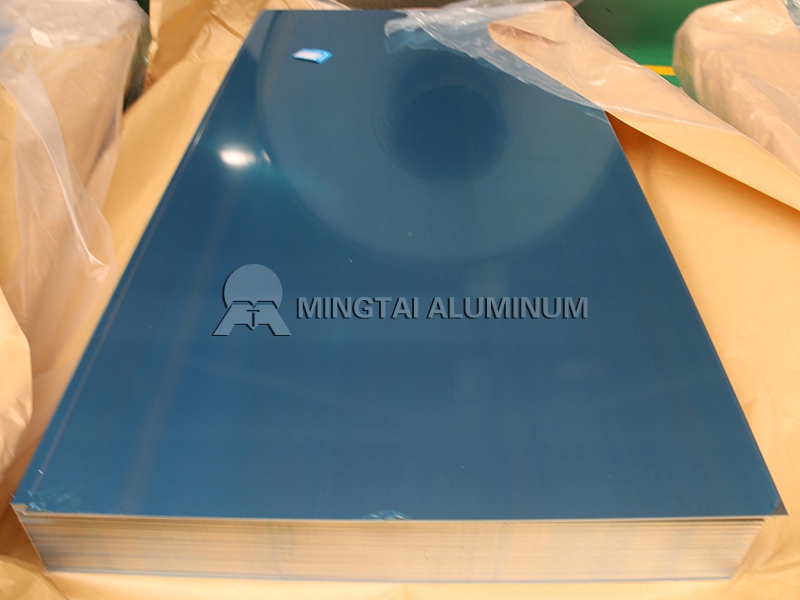

Die cast aluminum sheets have advantages over other aluminum plates, such as aesthetics, light weight, and corrosion resistance, which make them popular among the masses. Especially since the lightweight of automobiles, die-cast aluminum sheets have been widely used in the automotive industry. In particular, the surface of the die-cast aluminum plate is more beautiful after being treated, and is more popular among consumers!

1.Powder spraying (ie powder spraying): Powder spraying is to spray the powder coating onto the surface of the die-cast aluminum plate by powder spraying equipment. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating. The powder coating is solidified by high-temperature baking and becomes the final coating of different kinds of effects of powder coating; the spraying effect of powder coating is superior to the painting process in terms of mechanical strength, adhesion, corrosion resistance and aging resistance, and the cost Also under the same effect of painting. Powder spray, roughly divided into outdoor powder and indoor powder. The texture can be adjusted into a variety of effects, such as smooth, sand, foam and so on.

2.paint treatment: the real paint process is aluminum alloy phosphating after spraying, spraying and then baking, such a coating is not only anti-corrosive and bright and wear-resistant, not easy to fall off.

Surface pretreatment: degreasing, water washing, rust removal, water washing, surface conditioning, water washing, phosphating, water washing, water washing, drying.

The purpose of the pre-painting treatment is to obtain a good coating. Since the above stamping parts are in the process of manufacturing, processing, handling and storage, there will be grease, oxide scale, dust, rust and corrosive substances on the surface, if not removed. It directly affects the performance, appearance, etc. of the coating film, so the pretreatment plays an extremely important role in the coating process.

3.Injection treatment: injection is the name of the surface coating processing of industrial products, fuel injection processing is generally specialized in plastic injection, silk screen, pad printing; EVA, rubber and other shoe materials color, silk screen. With spraying line, silk screen, pad printing machine and other equipment, and according to customer requirements, production of high temperature, friction, UV, alcohol, gasoline and other products. Processing range: electronic products: ordinary spray paint, PU paint, rubber paint (hand paint), difficult to solve problems encountered in spray injection molding, such as gas lines, weld seams, etc., with experience in spraying rubber paint (hand paint), with Feel paint rework technology.

4.Oxidation treatment: oxidation of aluminum alloy surface, suitable for conductive oxidation, aluminum or aluminum profiles, suitable for anodizing.

The oxidation color of aluminum alloy generally has natural color and sky blue. Anodizing is carried out under high voltage conditions. It is an electrochemical reaction process; conductive oxidation does not require electricity, but only needs to be immersed in the syrup. It is a pure chemical reaction. Anodizing takes a long time, often tens of minutes, while conductive oxidation requires only a few tens of seconds.

5.Sand blasting: Spray a layer of fine sand on the surface of the aluminum alloy to enhance the friction coefficient of the contact surface, which can enhance the reliability of the connection. The thickness and texture of the sand-free aluminum alloy profiles are also very different.

6.Electroplating: Electroplating is the process of depositing a metal or alloy on the surface of a workpiece by electrolysis to form a uniform, dense, and well-bonded metal layer. The application of electroplating process is generally used for the following purposes: anti-corrosion, protective decoration, anti-wear.

The surface treatment of die-cast aluminum sheets generally includes: powder spraying (ie, powder coating), baking paint, fuel injection, oxidation, sand blasting, electroplating, and the like. According to the thickness and finish of the surface treatment of the product.