6101 T63 T64 aluminum sheet alloy for Busbar

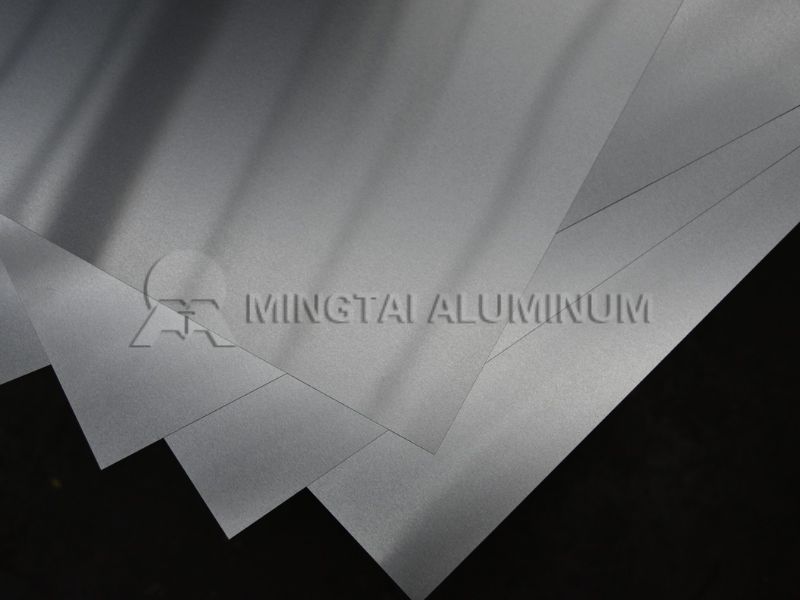

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

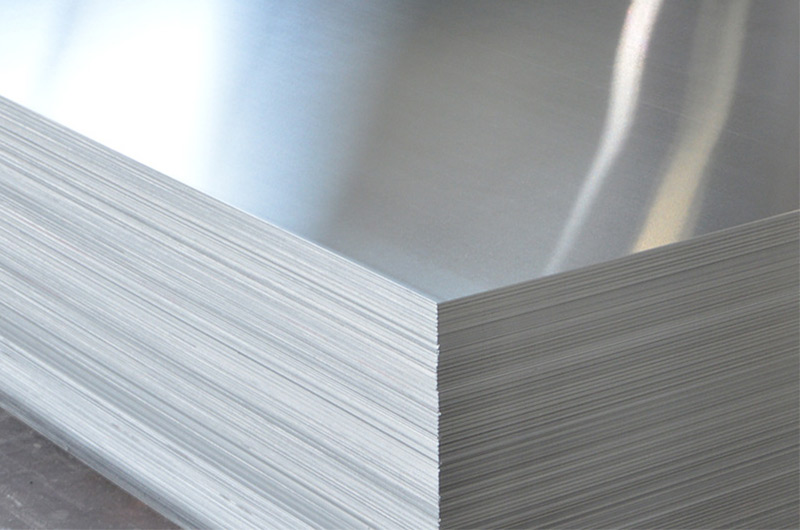

In the field of electrical power distribution and transmission, busbars, as key components for carrying and distributing current, have their material selection directly impacting the system’s efficiency, safety, and service life. 6101 T63 T64 aluminum sheet alloy busbars are high-performance materials specifically designed for such demanding applications and have become a preferred choice for industrial and commercial busbar systems.

Why Choose 6101 T63 T64 aluminum sheet Alloy?

6101 aluminum belongs to the Al-Mg-Si series of heat-treatable alloys, renowned for its excellent electrical conductivity, good mechanical strength, and superior corrosion resistance. Compared to pure aluminum, it maintains high conductivity while gaining significantly enhanced strength through heat treatment. Versus copper busbars, aluminum offers a distinct weight advantage, effectively reducing structural load and installation complexity, along with compelling cost-effectiveness.

Chemical Composition of 6101 aluminum plate sheet

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti |

| 6101 | 0.30-0.70 | ≤0.50 | ≤0.10 | ≤0.03 | 0.35-0.80 | ≤0.03 | ≤0.10 | ≤0.06 |

Mechanical Properties of 6101 T63 T64 aluminum sheet

| Alloy | Temper | Tensile strength

Rm(Mpa) |

Yield strength

Rp0.2(Mpa) |

Conductivity %|ACS | Bending |

| 6101 | T63 | ≥150 | ≥185 | ≥56% | 90°11 |

| 6101 | T64 | ≥55 | ≥105 | ≥59.5% | 90°11 |

6101 Aluminum Advantages as a Busbar Material

Superior Conductivity & Energy Efficiency: High electrical conductivity translates to lower electrical resistance and reduced line losses, offering significant energy savings and lower operational costs over the long term.

Excellent Strength-to-Weight Ratio: The T63/T64 tempers provide mechanical properties superior to standard aluminum, ensuring busbar stability under electromagnetic forces, thermal stress, and its own weight, while lightweight simplifies handling and installation.

Outstanding Corrosion Resistance: The naturally formed, dense oxide layer on the surface provides excellent resistance to corrosion in various environments, extending service life and minimizing maintenance.

Good Fabrication and Connection Properties: It is easily cut, drilled, and formed, facilitating on-site fabrication. Reliable, low-resistance connections to copper or other equipment can be achieved with proper surface preparation and connection techniques.

High Cost-Effectiveness & Sustainability: Material costs are typically significantly lower than copper while delivering comparable performance. Aluminum is abundant and fully recyclable, aligning with green building and sustainable development goals.

Typical Applications

Power distribution busways in industrial plants and power stations

High-density power distribution systems in data centers and telecom facilities

Main power risers and feeders in commercial buildings, hospitals, and airports

Power collection and interconnection in renewable energy

Power transmission in rail transportation and marine electrical systems