Aluminum copper alloy | Aluminum-copper alloy

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Introduction to aluminum copper alloy:

The aluminum copper alloy is very hard and has a melting point of 640 ° C. It is generally composed of 97% aluminum and 3% copper. Similar to the chemical properties of aluminum metal. Light and tensile strength. It can replace expensive copper wire as wire.

Aluminum copper alloy details:

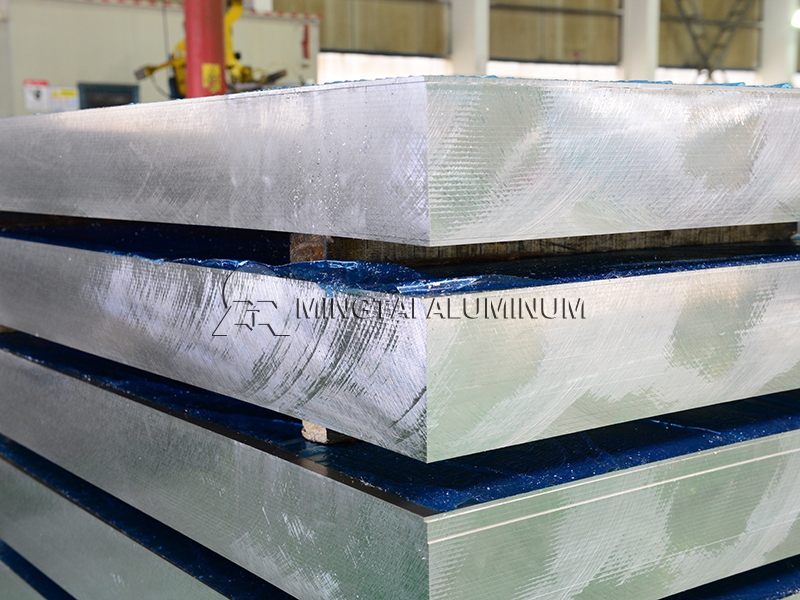

Aluminum copper alloy is the earliest cast aluminum alloy used in the industry. Its main performance characteristics are high room temperature and high temperature mechanical properties, simple casting process, good cutting performance and excellent heat resistance. It is the basis for the development of high strength aluminum alloys and various heat resistant alloys. The disadvantage is that the casting property of the solid solution alloy is poor, the potential difference between the copper-rich phase and the () substrate is large, the corrosion resistance is low, and the density is large.

Aluminum copper alloy is very hard and has a melting point of 640 ° C. It is generally composed of 97% aluminum and 3% copper. Similar to the chemical properties of aluminum metal. Light and tensile strength. It can replace expensive copper wire as wire.

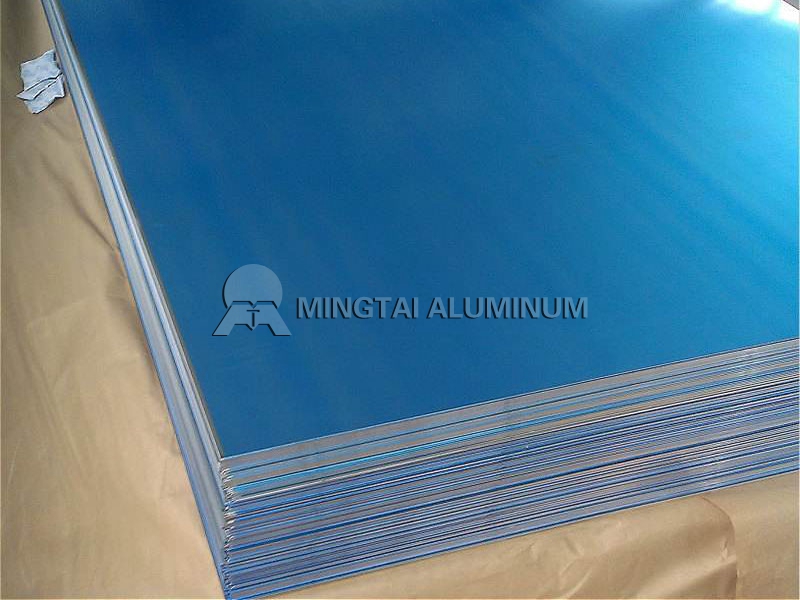

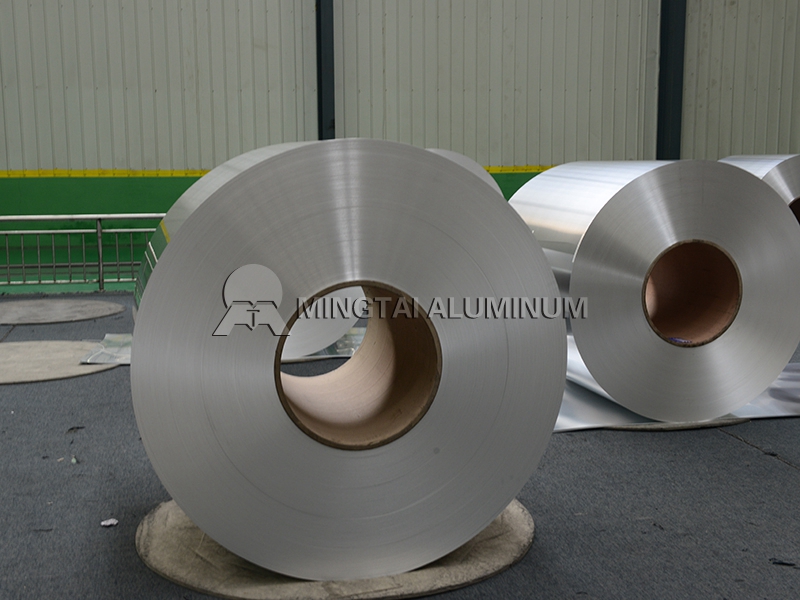

Aluminum-copper alloy can be made into sheets, profiles, forgings, wires, rods, tubes, foils, aerospace structural parts, electrode solder, machined products, engine piston wheels and more. The commonly used Aluminum copper alloy has 2024 aluminum plate.

Classification of aluminum copper alloys:

One grade of Aluminum-copper alloy is ZAICu10, codenamed ZL202, with a composition of Cu mass fraction = 9.0% to 11.0%, the remainder being Al, and the as-cast microstructure is divorced eutectic. The alloy is simple to smelt, has certain eutectic, and has good casting performance, but can not be heat-treated and can only be used in the as-cast state, so the mechanical properties are not high, and the new national standard GB/T 1173-1995 has been cancelled. standard.

Another grade of Aluminum copper alloy is ZAlCu4, codenamed Z1203, with a composition of Cu mass fraction = 4.0% to 5.0%, the balance being Al, and the as-cast microstructure being + a small amount. There is severe intragranular segregation. Because of its low copper content, the alloy can be solution treated. After quenching and aging treatment, the mechanical properties can be greatly improved. Due to the large solidification interval and poor casting performance, it is often used as a part with a simple shape to withstand moderate loads and work at a certain temperature.

Because the corrosion resistance of Aluminum copper alloy is not good, it is not widely used in industry.