1060 aluminum sheet surface treatment process

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

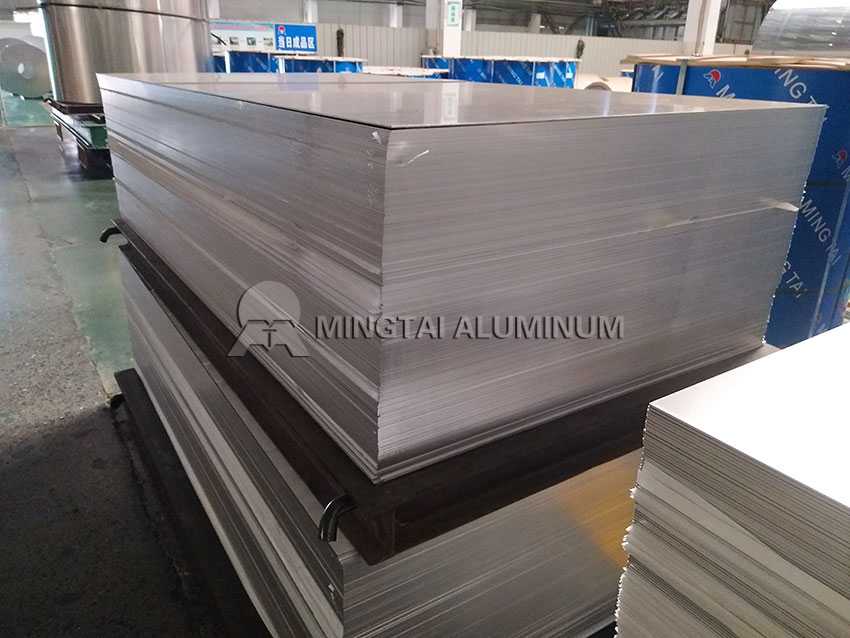

1060 aluminum sheet is a commonly used aluminum plate, which is also more common. There are several surface treatment methods for 1060 aluminum plate production. Here is a brief introduction. I hope to help you understand the 1060 aluminum plate.

1. Aluminum plate surface treatment process:

(1) pre-soaking: the three-layer aluminum alloy plate is respectively immersed in a sodium hydroxide solution and then blown dry by a blower;

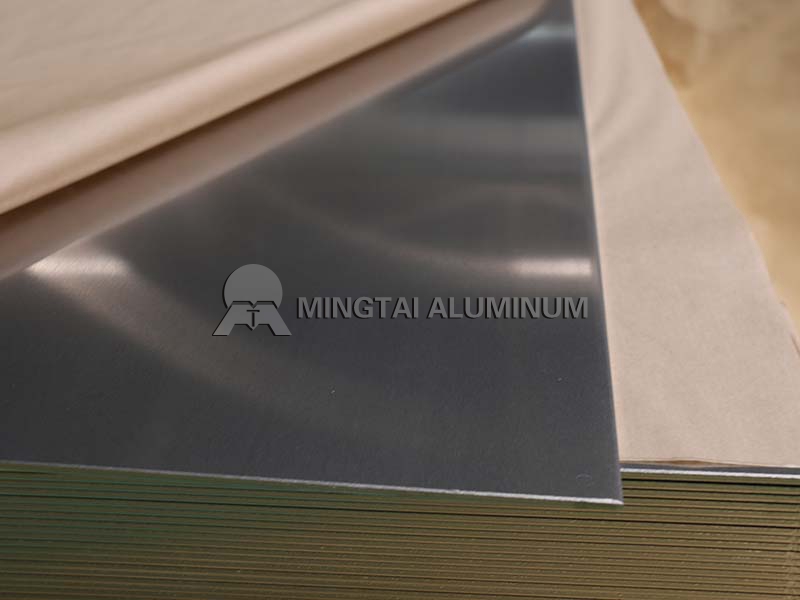

(2) Surface treatment: the lower surface of the upper aluminum alloy sheet, the upper and lower surfaces of the middle aluminum alloy sheet, and the upper surface of the lower aluminum alloy sheet are respectively polished using a steel brush;

(3) Surface cleaning: the polished three-layer aluminum alloy plate is cleaned with a brush, and the surface is cleaned by a suction pipe;

(4) Coating lubricant: The surface-cleaned three-layer aluminum alloy sheets are stacked into one body, and a layer of lubricant is applied on the upper surface of the upper aluminum alloy sheet and the lower surface of the lower aluminum alloy sheet.

2, 1060 aluminum plate surface treatment method:

(1) Multi-tone surface treatment, in order to make the 1060 aluminum plate meet various needs during use, the color treatment of the 1060 aluminum plate is more perfect for the 1060 aluminum plate, and the 1060 aluminum plate needs to be passed. After the polishing and oxidation treatment, the effect can be achieved.

(2), 1060 aluminum plate for electrophoretic painting, after treatment, the surface of 1060 aluminum plate will show a smooth side, and the corrosion resistance will also be enhanced.

(3), 1060 aluminum plate for powder electrostatic spraying treatment, so as to enhance the corrosion resistance of 1060 aluminum plate, to deal with acid and alkali salt materials, 1060 aluminum plate after powder electrostatic spraying is superior to oxidation coloring profiles.

(4), 1060 aluminum plate for frosting treatment, the surface of the patterned 1060 aluminum plate is very bright, but when used in many places, the light on the 1060 aluminum plate will be disturbed, and the frosting treatment can solve this problem well. The 1060 aluminum plate passes through The matte surface will be silky smooth and very popular on the market.

1060 aluminum sheet national standard aluminum content of more than 99.6%, also known as pure aluminum, is a commonly used series in the aluminum strip family. The advantages of this series of aluminum plates: the commonly used series, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage compared to other high-grade alloy aluminum plates. With good elongation and tensile strength, it can fully meet the normal processing requirements (stamping, drawing) and high formability. 1060 aluminum sheet is industrial pure aluminum with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, heat treatment can not enhance the machinability; gas welding, hydrogen atom welding and contact welding, not easy to braze; Easy to withstand various pressure processing and extension.