6016 Aluminum for Automotive Outer Body Panels

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

In order to continuously pursue lightweight vehicles, improve fuel efficiency, and extend the range of electric vehicles, automotive designers and engineers have begun to adopt advanced materials. Among these, 6016 aluminum alloy has become the preferred material for automotive exterior body panels, including doors, hoods, fenders, and trunk lids.

Understanding 6016 Aluminum Alloy: Composition and Core Characteristics

6016 is a heat-treatable Al-Mg-Si series alloy. Its carefully balanced composition provides an optimal blend of strength, formability, and surface quality.

Key Properties:

Excellent Formability: In its T4 temper, 6016 offers superior stretch forming and deep drawing capabilities, allowing for the creation of complex, aesthetically sharp panel designs without cracking.

High Bake Hardening Response: E-Coat baking at ~180°C, the alloy undergoes artificial aging, significantly increasing its yield strength. This means panels are soft during stamping but become strong and dent-resistant in the final product.

Superior Surface Quality: After stamping and painting, 6016 provides a Class-A surface finish, essential for the visible exterior of a vehicle.

Good Corrosion Resistance: It offers robust performance against environmental factors, contributing to vehicle longevity.

Effective Hemming Performance: It allows for clean, crack-free flanging and hemming operations to join outer and inner panels.

6016 vs. Other Common Automotive Aluminum Alloys

6016 vs. 5182 (Al-Mg Alloy):

5182 is non-heat-treatable, offering higher initial formability and used often for inner panels. However, 6016 provides a better surface finish and far superior bake-hardened strength, making it the clear winner for exterior outer panels where appearance and dent resistance are paramount.

6016 vs. 6111:

Both are Al-Mg-Si alloys. 6111 typically has higher copper content, giving it higher post-bake strength but slightly lower formability and corrosion resistance. 6016 offers a better overall balance for high-volume production, which is why it has become the European and increasingly global standard.

Applications in Modern Automotive Manufacturing

6016 aluminum sheet is specified by nearly every major OEM for their aluminum-intensive vehicles. You will find it in:

- Hoods

- Doors

- Fenders

- Liftgates / Tailgates

- Roof Panels

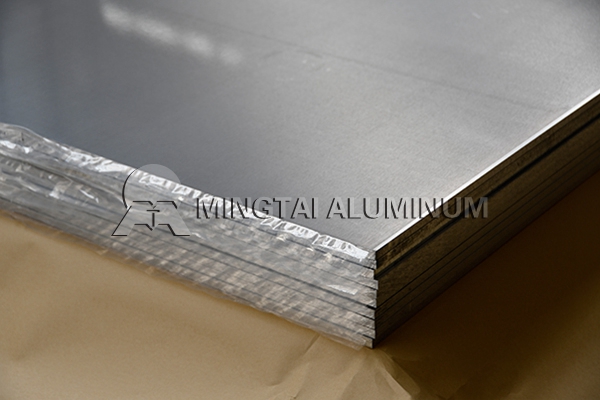

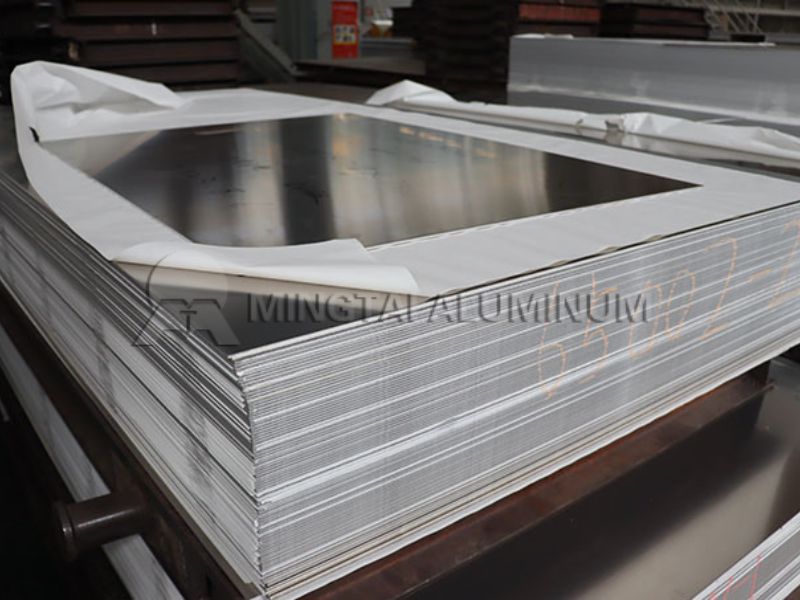

Partner with the Right Supplier for Your 6016 Aluminum Needs

Looking for a reliable partner for your next project? Mingtai Aluminum is a leading supplier of high-performance 6016 aluminum sheet and coil for the automotive industry. We provide high-quality 6016 aluminum sheet to ensure your lightweighting goals are achieved efficiently.