Medicine Aluminum Foil

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

Introduction of Medicine Aluminum Foil

Medicine aluminum foil has become a new type of pharmaceutical packaging material widely used in the world. Its main uses include blister packaging for pharmaceutical capsules and tablets, as well as bag-shaped packaging of powder granules and water. With technology updates and market expansion, medicine aluminum foil will usher in a broader market opportunity. As a large-scale medicine aluminum foil substrate manufacturer, Mingtai Aluminum has seized the current development opportunities and produced 8011 aluminum foil for pharmaceutical packaging, 8021 pharmaceutical aluminum foil and 8079 pharmaceutical aluminum foil, all of which have undergone strict pinhole detection, degreasing process and plate type control. Ensure that the produced aluminum foil of the drug can achieve ultra-high sealing performance in the later adhesive compounding process, and perfectly protect the quality of foil medicine. Below, we will introduce the aluminum foil products produced by Mingtai aluminum foil manufacture in detail.

Specific Use of Medicine Aluminum Foil

PTP medicine aluminum foil

It has good light-proof and barrier properties, and is easy to push open or puncture. It is convenient to take medicines and is suitable for packaging of medicines such as tablets, capsules and pills.

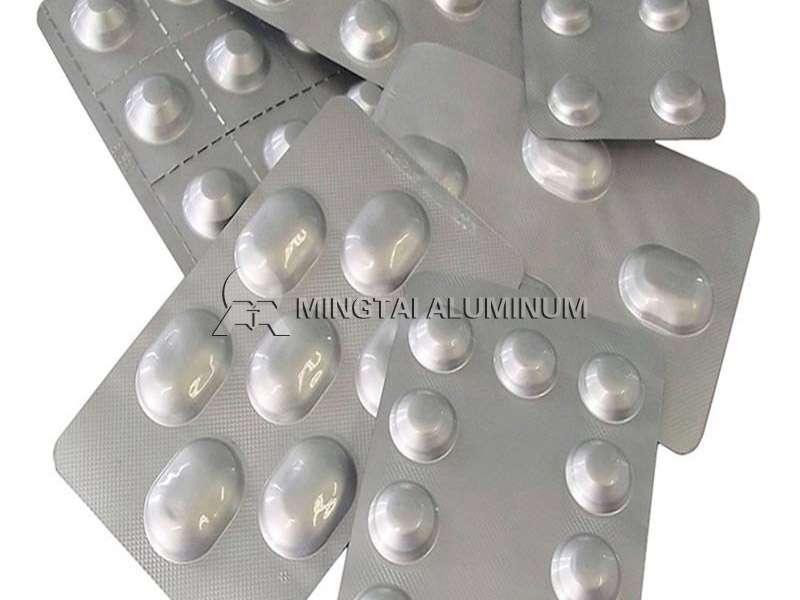

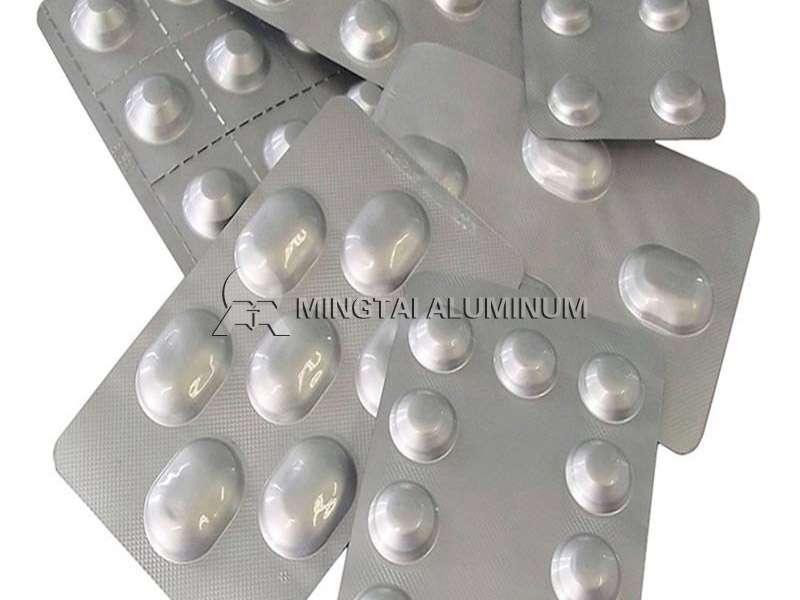

Aluminium foil for blister packaging

The blister pack is formed by placing the medicine in a blister or blister of a plastic molded plastic sheet, and then thermally bonding the plastic sheet to the aluminum foil which is printed and coated with a protective agent and a binder. Aluminum foil for blister packaging can be printed on one device at a time, coated with protective agent, adhesive coating process and corresponding drying process, suitable for mass production, so aluminum foil for blister packaging is also the main aluminum foil in the field of pharmaceutical.

Tropical medicine aluminum foil

The tropical medicine aluminum foil is a combination of a thermoformed plastic blister and a cold formed composite aluminum. The blister package maintains the bubble size and the area around the blister is slightly wider so that the cold formed tropical blister composite film can seal with the thermoformed blister makes up for the problem of non-blocking and poor water resistance in the traditional aluminum-plastic, and is gradually becoming one of the mainstream packaging methods. Its unique packaging design of child protection tropical medicine foil allows adults to open the medicine packaging, and children can not open, it can not affect the normal use, but also prevent children from taking drugs. Its emergence has caused widespread attention in the pharmaceutical industry.

Aluminum foil for medicine cover

The aluminum foil about the cap of the medicine bottle is a hot stamping material which is directly calendered into a sheet by metal aluminum, and the hot stamping effect is similar to that of the pure silver foil stamping, so it is also called a fake silverfoil. It has excellent moisture resistance, shading and high barrier ability, net, uniform color, no speckle. And more importantly, foil medicine is very safety and hygiene.

Advantages of Mingtai Medicine Aluminum Foil

1. Guaranteed, clean surface of aluminum foil

The mill has a good degreasing effect. According to many years of experience, Mingtai has modified the roller clearer of the rolling mill. Behind the exit activity device, the rear device is attached with a pair of oil retaining curtains near the supporting roller, and the splashing plate is cleaned. The air nozzle has been modified to achieve the best degreasing of the rolling mill itself, and the surface of the produced medicine aluminum foil is clean and safe.

2.No slack on both sides of the aluminum foil

Mingtai uses a cooling oil spray device on the roughing mill and performs regular inspection and maintenance to reduce the side or partial slack on both sides of the aluminum foil.

3. high tensile strength

Mingtai strictly controls the speed of aluminum foil rolling and the added alloy composition. The medicine aluminum foil produced has less impurities, high tensile strength and good performance.

Status and Technical Parameters of Medicine Aluminum Foil

PTP Medicine Aluminum Foil

Typical alloy:8011 aluminum foil

Material status:O、H18

thickness(mm):0.016-0.5

width(mm):100-1600

Typical products: Capsule cover, etc.

Aluminium Foil for Blister Packaging

Typical alloy:8021 aluminum foil

Material status:O

thickness(mm):0.04-0.065

width(mm):100-1600

Typical products: Blister packaging, etc.

Tropical Medicine Aluminum Foil

Typical alloy:8021 aluminum foil、8079 aluminum foil

Material status:O

thickness(mm):0.016-0.2

width(mm):100-1600

Typical products:High-end pharmaceutical packaging, etc.

Aluminum Foil for Medicine Cover

Typical alloy:8011 aluminum foil

Material status:H14 H16

thickness(mm):0.016-0.5

width(mm):100-1600

Typical products:Oral liquid aluminum-plastic compound cover, infusion bottle aluminum-plastic cover, etc