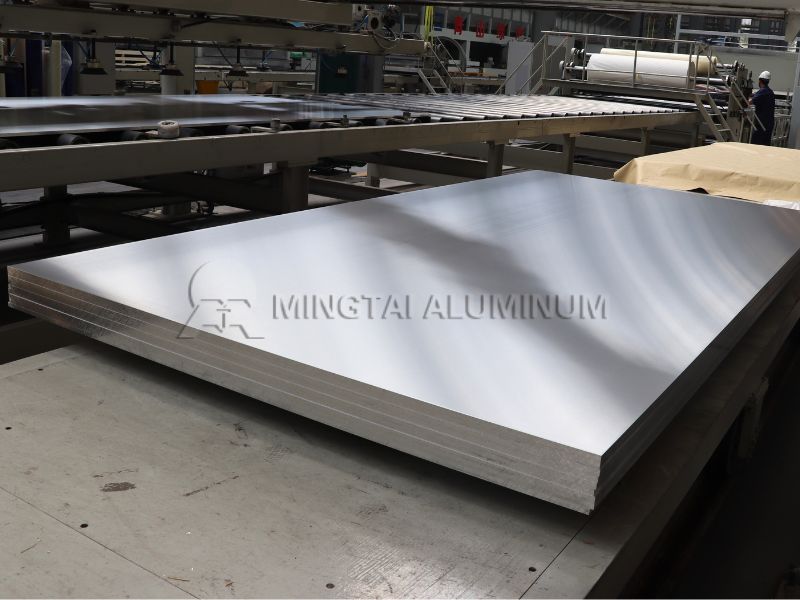

6082 Aluminum Plate for Highly stressed components

Sample: A4 Sized

Payment Terms: L/C,D/P,T/T

Delivery time: Within 15-30 Days

Email Us:sale06@mingtai-al.com

6082 aluminum plate is an excellent choice for highly stressed components due to its combination of high strength, good corrosion resistance, and weldability.

Key Properties of 6082 Aluminum Plate

- Corrosion Resistance: Good, especially in marine environments

- Weldability: Excellent (can be welded using TIG, MIG, or resistance welding)

- Machinability: Fair (better than 6061 in some cases)

- Fatigue Resistance: Good, making it suitable for dynamic loads

Typical Applications for Highly Stressed Components

Aerospace (structural parts, brackets)

Automotive (chassis components, suspension parts)

Marine (boat frames, hull reinforcements)

Construction (load-bearing structures, bridges)

Bicycle frames & high-performance machinery

6082 T6 T651 aluminum plate physical properties

| Temper | T6 | T651 |

| Density | 2.70 g/cm³ | 2.68g/cm³ |

| Tensile Strength | 250-310MPa | >=295MPa |

| Elongation | 10% | 8% |

| Thermal Conductivity | 170 W/m-K | 220.0 W/m-K |

Comparison with Other Alloys

| Alloy | Strength (T6) | Corrosion Resistance | Weldability | Best For |

|---|---|---|---|---|

| 6082 | High (310-340 MPa) | Very Good | Excellent | High-stress structural parts |

| 6061 | Slightly lower (290 MPa) | Good | Excellent | General-purpose applications |

| 7075 | Very High (500+ MPa) | Poor (requires coating) | Poor (cracking risk) | Aerospace |

For highly stressed components that require a balance of strength, weldability, and corrosion resistance, 6082-T6 aluminum plate is an excellent choice. It outperforms 6061 in strength and is more versatile than 7075 in terms of fabrication

Would you like recommendations on specific thicknesses for your application?

Contact us

📧 Email: sale06@mingtai-al.com

📱WhatsApp: wa.me/+86-17320140933